Note: Coffee and snacks willl precede the seminar at 3 p.m. in the Ford ES&T first-floor atrium

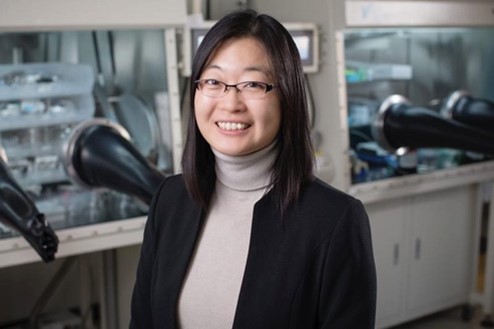

Ying Diao, University of Illinois, Urbana-Champaign

"Non-Equilibrium Assembly for Additive Manufacturing of Functional Polymers"

Abstract:

Printing technologies have the potential to revolutionize manufacturing of electronic and energy materials by drastically reducing the energy cost and environmental footprint while increasing throughput and agility. For instance, printing organic solar cells can potentially reduce energy payback time from 2-3 years to as short as 1 day! At the same time, additive manufacturing of such functional materials brings a new set of challenges demanding exquisite control over hierarchical structures down to the molecular-scale. We address this challenge by understanding the evaporative assembly pathway and flow-driven assembly central to all printing processes. We discover a surprising chiral liquid crystal mediated assembly of achiral semiconducting polymers in an evaporating meniscus. We uncover the molecular assembly mechanism and further show that the chiral helical structures can be largely modulated by controlling printing regimes. Such new topological states of semiconducting polymers can empower unprecedented control over charge, spin and exciton transport, reminiscent of how Nature efficiently transfer electrons and transduce energy using chiral helical structures. The ability to control non-equilibrium assembly during printing sets the stage for dynamically modulating assembled structures on the fly. We demonstrate this concept by programming nanoscale morphology and structure color of bottlebrush block copolymers during 3D printing. This approach holds the potential to reduce the use of environmentally toxic pigments by printing structure color. Complementing the above hypothesis-driven approach, we are pursuing data-science driven approach to drastically accelerate discovery and manufacturing of functional polymers. By linking automated synthesis, testing and machine learning in a close-loop, we are able to optimize function highly efficiently while discovering new physical insights for transferring closed-loop optimization into hypothesis driven discovery.

Bio:

Ying Diao is an Associate Professor, University Scholar and Dow Chemical Company Faculty Scholar in Department of Chemical and Biomolecular Engineering at University of Illinois at Urbana-Champaign. She serves as the Co-Chair of Molecular Science and Engineering in the Beckman Institute of Advanced Science and Technology, and a Thrust Lead of the Molecular Maker Lab Institute - an NSF AI Institute. She received her Ph.D. degree in Chemical Engineering from MIT in 2012. Her doctoral thesis was on understanding heterogeneous nucleation of pharmaceuticals by designing polymeric substrates. In her subsequent postdoctoral training at Stanford University, she pursued research in the thriving field of printed electronics. Diao group, started in 2015 at Illinois, focuses on understanding assembly of organic functional materials and innovating printing approaches that enable structural control down to the molecular and nanoscale. She has over 100 publications which have been cited close to 10,000 times. Her work has been frequently featured in scientific journals and news media. She is named to the MIT Technology Review’s annual list of Innovators Under 35 as a pioneer in nanotechnology and materials. She is also a recipient of NSF CAREER Award, NASA Early Career Faculty Award, 3M Non-Tenured Faculty Award and was selected as a Sloan Research Fellow in Chemistry as one of the “very best scientific minds working today”.